Professor Emeritus

Professor EmeritusB.Sc. (Shizuoka), M.Eng. (Shizuoka), Ph.D. (Toronto), P.Eng.

Director, Pulp & Paper Centre

Room: WB365 | Tel.: 416-978-8585 | Email: honghi.tran@utoronto.ca

Awards

Paper Industry International Hall of Fame, 2017

TAPPI Gunnar Nicholson Gold Medal Award, 2017

Canadian Academy of Engineering Fellow, 2016

PAPTAC Fellow, 2015

Research Leader Award, Faculty of Applied Science & Engineering, U of T, 2015

TAPPI Engineering Technical Award and Beloit Prize, 2006

PAPTAC John S. Bates Gold Medal, 2014

ICRC Lifetime Achievement Award, 2014

Frank Dottori Chair in Pulp and Paper Engineering, 2006

TAPPI Engineering Technical Award and Beloit Prize, 2006

TAPPI Research & Development Technical Award and the William H. Aiken Prize, 2003

TAPPI Fellow, 2000

Memberships

Pulp and Paper Technical Association of Canada (PAPTAC)

Technical Association of the Pulp and Paper Industry (TAPPI)

Canadian Academy of Engineering (CAE)

Professional Engineers of Ontario (PEO)

Research Interests

Most industrial plants, especially those in the pulp and paper, steel, mining, petroleum and tar sand industries, require large amounts of power, high pressure steam, water and chemicals to operate. Effective utilization, generation and regeneration of these essentials are of vital importance to the productivity, economy and environmental sustainability of the plants.

Our “Energy & Chemical Recovery” research has evolved greatly since its initiation in 1987. The goals have been to obtain fundamental information on the equipment and process involved, and to use the obtained information to develop viable technologies/strategies to increase the energy production and chemical recovery efficiencies of the process, particularly that in the pulp and paper industry. Over the years, we have successfully conducted 12 large industrial research consortia on problems encountered in kraft pulp mills.

Our current research activities are in three main areas: energy and chemical recovery in the kraft pulping process, combustion characteristics of biomass and mixed fuels, and mill waste disposal and utilization. These fields of research are interdisciplinary, involving chemical engineering, combustion, reaction kinetics, heat transfer, fluid mechanics, computer modelling (thermodynamic, dynamic and CFD) and bioengineering.

There are presently over 30 researchers involved in the research program including 15 graduate students, 3 research staff and 10 professors in the Departments of Chemical Engineering & Applied Chemistry, Mechanical Engineering & Industrial Engineering, and Electrical & Computer Engineering, and the Pulp & Paper Centre at the University of Toronto. Students often have opportunities to visit plants, conduct field trials, present their work at industrial meetings and conferences, and interact directly with other faculty and industry on problems of economic and social importance.

Research Areas

Energy and Chemical Recovery in the Kraft Pulping Process

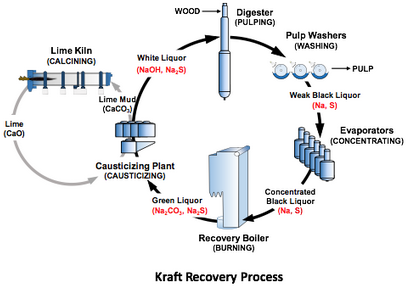

The kraft process is the most important method for producing wood pulp for papermaking. It uses a hot aqueous solution of NaOH and Na2S to dissolve the wood lignin and separate the pulp fibres. The recovery of the cooking chemicals is attained through: i) concentrating the spent liquor (black liquor); ii) burning the concentrated black liquor in a recovery boiler to produce steam and power and molten smelt, Na2S and Na2CO3; iii) dissolving the smelt in water to produce green liquor, which is then causticized with lime (CaO) to regenerate NaOH; and iv) separating the precipitated lime mud (CaCO3) from the white liquor, and burning the mud in a lime kiln to regenerate lime.

The kraft process is the most important method for producing wood pulp for papermaking. It uses a hot aqueous solution of NaOH and Na2S to dissolve the wood lignin and separate the pulp fibres. The recovery of the cooking chemicals is attained through: i) concentrating the spent liquor (black liquor); ii) burning the concentrated black liquor in a recovery boiler to produce steam and power and molten smelt, Na2S and Na2CO3; iii) dissolving the smelt in water to produce green liquor, which is then causticized with lime (CaO) to regenerate NaOH; and iv) separating the precipitated lime mud (CaCO3) from the white liquor, and burning the mud in a lime kiln to regenerate lime.

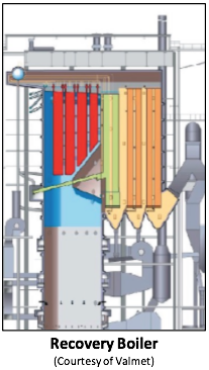

For each ton of pulp produced, kraft pulp mills generate roughly ten tons of weak black liquor which contains water, spent chemicals and dissolved wood components. Although concentrated black liquor is an important biofuel, it is difficult to burn because of its high ash content from the pulping chemicals, low ash melting temperature and low heating value. Massive ash deposit accumulation on heat transfer surfaces is a persistent problem in many recovery boilers. Deposits drastically reduce the thermal efficiency of the boiler, and in severe cases, may lead to complete plugging of flue gas passages, requiring up to two days of costly downtime to remove the deposits. The combustion environment in the boiler is extremely corrosive, limiting the boiler operating steam temperatures and pressures, which affect the power production efficiency.

For each ton of pulp produced, kraft pulp mills generate roughly ten tons of weak black liquor which contains water, spent chemicals and dissolved wood components. Although concentrated black liquor is an important biofuel, it is difficult to burn because of its high ash content from the pulping chemicals, low ash melting temperature and low heating value. Massive ash deposit accumulation on heat transfer surfaces is a persistent problem in many recovery boilers. Deposits drastically reduce the thermal efficiency of the boiler, and in severe cases, may lead to complete plugging of flue gas passages, requiring up to two days of costly downtime to remove the deposits. The combustion environment in the boiler is extremely corrosive, limiting the boiler operating steam temperatures and pressures, which affect the power production efficiency.

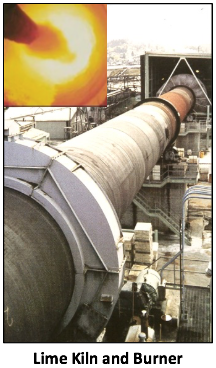

The overall thermal efficiency of the recovery boiler depends strongly on the solids content of the concentrated black liquor, which in turn depends on the performance of the evaporators. The thermal efficiency of the lime kiln, on the other hand, determines the amount of fossil fuel required for calcining lime. A well-insulated, controlled, modern lime kiln may need as little as half of the fuel used by a poorly-operated kiln. There are many problems encountered in lime kiln operation, including poor lime quality, poor kiln refractory performance, deposit and ring formation on kiln lining surfaces, dusting, scaling on induced-draft fan blades, and gaseous emissions. These problems greatly reduce the kiln throughput and reliability.

The overall thermal efficiency of the recovery boiler depends strongly on the solids content of the concentrated black liquor, which in turn depends on the performance of the evaporators. The thermal efficiency of the lime kiln, on the other hand, determines the amount of fossil fuel required for calcining lime. A well-insulated, controlled, modern lime kiln may need as little as half of the fuel used by a poorly-operated kiln. There are many problems encountered in lime kiln operation, including poor lime quality, poor kiln refractory performance, deposit and ring formation on kiln lining surfaces, dusting, scaling on induced-draft fan blades, and gaseous emissions. These problems greatly reduce the kiln throughput and reliability.

If biomass, such as wood waste, mill sludges, saw dust, biosludge, biofuel produced from gasification/pyrolysis of biomass, and lignin precipitated from black liquor, can be effectively and economically converted into biogas and bio-oil to replace fossil fuels in the lime kiln and other processes, it will be an attractive option for pulp and paper mills to implement. This will not only reduce the energy cost, but also help alleviate the future dependence on fossil fuels of the pulp and paper industry, minimize sludge disposal problems and reduce net CO2 emissions

Combustion Characteristics of Biomass and Mixed Fuels

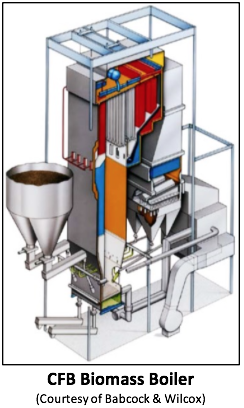

Kraft pulp mills typically need 30 GJ of steam and 850 KWH of power per ton of pulp produced. About 70% of the energy required is self-supplied by burning black liquor in recovery boilers; the remaining is by burning biomass (bark, wood waste, sawdust, mill sludge, etc.) in power boilers and from local utility stations.

Kraft pulp mills typically need 30 GJ of steam and 850 KWH of power per ton of pulp produced. About 70% of the energy required is self-supplied by burning black liquor in recovery boilers; the remaining is by burning biomass (bark, wood waste, sawdust, mill sludge, etc.) in power boilers and from local utility stations.

Burning non-traditional fuels in biomass boilers, recovery boilers and lime kilns can be problematic, due to the large difference in composition, moisture content, heating value and combustion behavior of the individual fuels. For instance, burning high S containing petroleum cokes and high Na containing precipitated lignin in a lime kiln may lower the product lime quality and kiln thermal performance, and lead to more frequent kiln outages due to ring formation. Mixing the biosludge with black liquor and burning it a recovery boiler may affect the burning behavior of black liquor, and introduce undesirable non-process elements into the recovery cycle, and alter the S and Na balances of the mill. Burning mill sludge, construction waste, shredded tires, peat, straw and petroleum coke in a biomass boiler may lead to high-temperature corrosion associated with high S, Na, K, Cl, V and Zn contents in the fuels, and excessive deposit formation on tube surfaces due to the low melting temperature of the fly ash. The practice also leads to high SOx, NOx and particulate emissions, and alters the composition, pH and leachability of the resulting ash, making it more costly to dispose.

Current Research Projects

- Factors affecting particulate removal efficiency of electrostatic precipitators

- Interaction between sootblower jets, tubes and deposits

- Molten smelt shattering with steam jets

- Smelt dissolution in the recovery boiler dissolving tank

- Hard scale formation in green liquor systems

- Effects of non-process elements on chemical recovery operations

- Sulfur and sodium balances in the recovery process

- Effects of feedstock variability on biomass boiler operation

- Biosludge characterization

- Methods for improving biosludge dewatering efficiency

- Drying and burning behaviours of biosludge

- Factors affecting settling and filterability of dregs

- Dregs characterization, disposal and utilization

- Converting mill waste into valuable products

The industrial relevance of the research projects and the high productivity of the research group have attracted significant support from the pulp and paper industry, as well as matching funding from NSERC and other sources. Our research partnership is international in scope involving companies and researchers in Canada, the United States, Finland, Sweden, Brazil, Chile and United Kingdom.

Industrial Partners (Last 5 Years)

- Andritz

- Arauco

- AV Group

- Babcock & Wilcox

- Boise

- Celulose Nipo-Brasileira

- Clyde-Bergemann

- Daishowa-Marubeni International

- Domtar

- ERCO Worldwide

- Eldorado Brazil

- Fibria

- FPInnovations

- International Paper

- Irving Pulp & Paper

- Klabin

- Kiln Flame Systems

- SAPPI

- Södra

- Stora Enso

- Suzano Celulose

- Tembec

- Canadian Kraft Paper

- Valmet

- WestRock

Selected Publications

- Doroudi, S., Pophali, A., Bussmann, M., Tandra, D., and Tran, H.N., “Modeling Sootblower Jet Effectiveness with Ansys Fluent”, Journal of Science & Technology for Forest Products and Processes: Vol.4, No.4, p.30-35 (2015)

- Orang, N. and Tran, H.N., “Effect of Moisture Content on Biomass Combustion”, TAPPI Journal, Vol.14, No.10, October, p.629-637 (2015)

- Zhao, L., Tran, H.N., and Maki, K., “Combustion Behaviour of Lignin and Lignin-lean Black Liquor”, TAPPI Journal, Vol.14, No.7, p.451-458 (2015)

- Montes, A., Ghiasi, E., Tran, H.N., Xu, C., “Study of bed material agglomeration in a heated bubbling fluidized bed using silica sand as the bed material and KOH to simulate molten ash”, Powder Technology, 291, p.178-185 (2016)

- LePage, H., Wong, W., Bussmann, M. and Tran, H.N., “Acoustic Analysis of Dissolving Tank Operation and Shattering Efficiency”, TAPPI Journal, Vol. 15, No.9, p.591-596 (2016).

- Hovey, G., Allen, D.G., Tran, H.N., “Drying Characteristics of Biosludge from Pulp and Paper Mills”, TAPPI Journal, Vol. 16, No.8, p.465-473 (2017).

- Tran, H.N. and Jones, A.K., “Formation Mechanisms of Jellyroll Smelt in Kraft Recovery Boilers”, TAPPI Journal, Vol. 16, No.10, p.597-605 (2017).

- Mohanan, G., Tran, H.N., Bussmann, M., and Manning, R., “Effect of Ring Formation on Burner Flame Stability in Lime Kilns”, TAPPI Journal, Vol. 17, No.5, p.285-293 (2018).